Rotten Sheathing

I was approached by a frantic client who had experienced a flood. They were getting bids from “every roofer in the book,” so to speak. Fall was quickly approaching, and they knew that they had an urgent problem that needed to be solved in a hurry. Little did they know that beyond the leak they had experienced, they had a much larger, very scary problem lurking. It being Halloween season and all, solving a scary problem intrigued me.

I am no stranger to solving roofing issues, and had done research in the past to solve similar problems with confidence. Rarely are two roof issues the same, and being a building science nerd, I felt grounded in theory. The history of why it failed was comical. The truth is that most roofers will do whatever you ask them to. That goes for insulators too.

Case Study

Faulty Ridge Vent

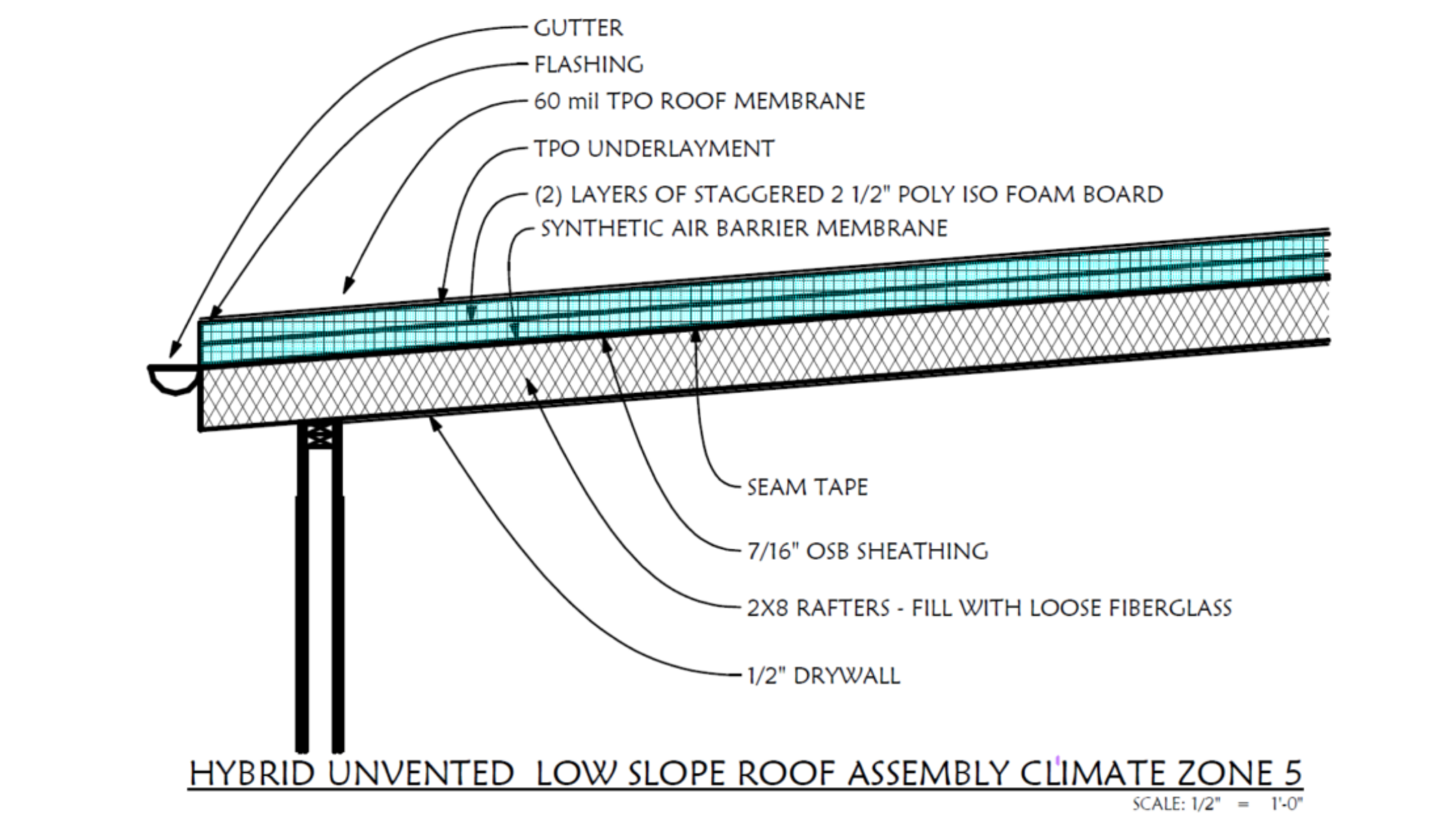

The home has a pitch of .5 / 12 with 2 x 8 rafters 16″ OC. It had a thin craft back insulation on top of the drywall. It used to have a tar and gravel roof, but this had been changed out within the last 5 years to an unknown membrane roof. I believe that the assembly was originally vented, because every joist space had a 2.5″ diameter screened plug that looked original. When I learned of the problem, someone had installed a wimpy ridge vent system without a Boston ridge.

The failure tipping point came when the client decided several years prior to stuff the joist space with insulation (because they were losing all their heat through the roof), inadvertently changing it to an unvented roof assembly. This chain of events caused the roof sheathing to gradually disintegrate.

The Background:

Rot happened as the cold air from outside met with the warm air from inside at the underside of the roof sheathing and condensed. Essentially, it rained from the inside. Condensation formed on the underside of the roof membrane, which, when exposed to the heat of the home, rapidly accelerated the plywood’s demise.

We are solidly in climate zone 5 here in Boise, Idaho and had experienced a cataclysmic 2016 winter event. By all accounts, with heavy snow and a protracted cold snap, this created ice dams (a term that few here had ever heard of) and caused water to roll into a ridge vent that ruined a central portion of the ceiling. Was it a blessing in disguise? I think so, because it brought the other, more serious problem to light. Like the proverbial Grandpa Ben’s report from the dentist… “-Ben, your teeth are fine, but your gums gotta go.”

Chief Complaint or Chief Problem?

When I got involved, the inside of the home had been dried out and we were just following orders, replacing drywall and painting. Arguably, the cart had been put solidly in front of the horse. We were fixing the chief complaint -the drywall issue-, but the chief problem was the faulty roof. The client finally gave me control of the project out of exasperation, trying to determine whose bid to accept. Every roofer had a different plan. Most wanted to re-roof the building just like they had been asked to do. Although a new roof was needed, putting new roofing over punky sheathing and a faulty assembly would have only disguised the problem allowing it to return the following winter. We call this “putting makeup on a pig.”

The Big Fix:

The details

I was able to earn my client’s trust by explaining that the roof needed a thermal brake, and that meant the solution was to insulate from above. This led me to contact my engineer and my insulation contractor, who shared a case study from Chicago (also in climate zone 5) where they had experienced similar failures. I also learned that there had been a recent series of failures in new homes in the Boise area that had tried using only 2.5 inches of foam board which was inadequate in creating a thermal brake. (Not up to 2012 IRC code, but they had gotten away with it.)

Our initial plan was to stick with a vented roof assembly. That is when I read an article by Joseph Lstiburek, ASHRAE Fellow B.A.Sc., M.Eng., Ph.D., P.Eng., an industry expert who had recently written an article about how to solve similar issues. I emailed him about my plan and was curious if venting the roof was an approved method. He responded quickly, saying that it would work, but asked one key question: “Joe, why would you want to do that? An unvented assembly would improve the thermal properties of the assembly.” Duh. I love it when the answer is so obvious.

I thanked him profusely, and redrew our assembly plan in the nick of time.

Proof Is In the Puddin’

With the home put back together properly (up to 2012 IRC code) and the residents returned, we believe we have solved a myriad of issues. In doing so, I get to take some well-deserved credit for understanding, taking charge, and fixing a serious problem correctly. This is problem solving at its best, which is what remodeling with Levco Builders is all about.

Your comments are welcome. To ask questions or get more information about remodeling, click here to email me directly, or call 208-947-7261

If you or someone you know is considering remodeling or just wants to speak to a trustworthy remodeling contractor, please contact me. You’ll be glad you did.

I learn something new every time I read your articles! Thanks

Thank you, I find that having a place to share and store things I discover is wonderful. I’m glad you find something of interest within the lines.

Congratulations Detective Joe. It’s so nice to hear about a builder who really solves the problems!

Wow that means a lot to me, I think all remodeling contractors are problem solvers down deep, they just have no way to share their successes. This is where the gooey center part of my job dwells. Just call me Inspector Clouseau from here on out.